Weighing Bugsby

With A Bathroom Scale

Bugsby on the scale |

Jump to:

Old dogs and new tricks

Lynn needs the accurate weight of Bugsby so that he can analyze the performance data collected with his Race Technology DL1 Data Logger. Using a procedure that he successfully applied to determining the weight of AtomAnt, Lynn utilized a bathroom scale to determine an accurate weight for Bugsby.

The concept ...

The concept ...

|

The realization ...

The realization ...

|

A construction detail to increase accuracy

A construction detail to increase accuracy

|

The scale is adjusted to read zero (tare)

The scale is adjusted to read zero (tare)

|

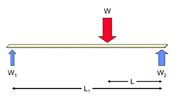

The diagram depicts the general concept of how to use a lever to multiply (scale up) the weight range of a bathroom scale. Underneath one end of a beam (a strong wooden board, for example) one places an ordinary bathroom scale. Under the other end of this beam is a block (stack of bricks, for example) so that the beam is level and horizontal to the ground. One can regulate how much weight registers on the scale (W1) by adjusting where the car wheel's weight (W) sits on the beam. In this version of the device, Lynn uses a L1:L ratio of 3:1. Consequently the car corner weight (W) is exactly three times the weight that's registered on the scale.

Lynn cuts a 1/8" slot in the board, and uses PVC pipe to more precisely control the position at which the weight contacts the board. Using this technique, Lynn feels that he can accurately predict the lengths to within about 1/8".

The PVC pipe is attached to the board with screws, and who's heads are filed smooth to reduce gouging of the scale, tire or brick. Also note the piece of heavy cardboard between the scale and the end of the board. This protects the scale's delicate surface from damage once the car's considerable weight is applied to the narrow contact point. Lynn didn't follow these additional steps when he weighed AtomAnt and Lynn's wife made him buy a new scale to replace the one he damaged.

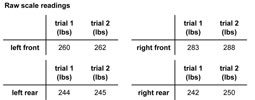

Lynn adjusts the scale so that it reads zero with the board and without the car. This technique subtracts the tare (empty) weight of the mechanism. A stack of bricks is placed under the other wheels so that the car remains level during the measurement. After positioning the scale under a wheel, the car needs to be "rocked" on its suspension so that the weight is properly redistributed between the corners. Lynn made two complete weighings of each corner of the car. Lynn observes that his reading appears to be repeatable within about +2 lbs.

The root-mean-square error in the measurement due to the combination of the uncertainty in the length and weight measurements is less than +5 lbs in the final measurement.

Bugsby weighs about 3139 lbs +-56 lbs (fuel) + driver + cargo

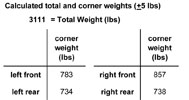

The following tables display the raw scale measurements and the calculated weights for Bugsby. Bugsby had about 1/4 tank of fuel (about 4.5 US gallons, or about 27.9 lbs = 4.5 gal * 6.2 lbs/gal) when the measurement was made. With a half tank of fuel, Bugsby will weigh about 3139 lbs, or about 3195 lbs with a full tank. For road performance measurements one also needs to add the weight of the driver plus any additional cargo.The value of 3139+56 lbs agrees well with the shipping weight of 3130 lbs listed in the 1926 and 1929 editions of the Branham Automobile Reference Book (Ben P. Branham Company, Chicago). As weighed, Bugsby is missing a roof frame+fabric and shock absorbers that would have been included in the factory shipping weight.

Raw scale measurements ...

Raw scale measurements ...

|

Computed vehicle weights ...

Computed vehicle weights ...

|

While the rear corners of Bugsby are fairly well balanced, this isn't true for the front corners. From the corner weights one notes that the right-front corner of Bugsby is about 74 lbs heavier than the left-front corner. This is most likely due to the steering wheel/column/box and brake/clutch/accelerator pedals that are on the right side.

Bugsby is fairly evenly weighted between the front and rear wheels, with 53% of the weight on the front wheels and 47% of the weight on the rear wheels. A full tank of fuel would bring the front/rear percentages closer to 52%/48%. Since this car has two-wheel mechanical brakes on the rear wheels, a greater fraction of the weight in the rear would likely improve its stopping performance.

Contact

with your comments or questions

with your comments or questionsCopyright © 2018 Lynn Kissel

Last updated: May 24, 2009