|

Crunch Time —

The Big Push For Hartford

D Day! The result of many weeks of hard work, Bugsby is strapped in

and ready for the road trip to Hartford.

|

- D Minus 21 (May 21, 2006)

- D Minus 15 (May 27, 2006)

- D Minus 13 (May 29, 2006)

- D Minus 11 (May 31, 2006)

- D Minus 7 (June 4, 2006)

- D Minus 6 (June 5, 2006)

- D Minus 4 (June 7, 2006)

- D Minus 2 (June 9, 2006)

- D Minus 1 (June 10, 2006)

- D Day (June 11, 2006)

|

D-21:

The state of Bugsby 21 days before Lynn intends to depart for Hartford. Does this vehicle

look ready for the show to you?

|

Lynn has already made a deal with himself that he would not compromise his restoration efforts

with Bugsby in spite of the fast approaching date of the

100 year anniversary celebration

of the Kissel Motor Car Company.

The event is scheduled for June 17, 2006, in Hartford, Wisconsin.

Lynn and Jeanne will trailer Bugsby to Hartford and they plan to leave Livermore on Sunday, June 11, 2006

— D-Day (departure day).

Lynn has assumed that he will have a running drive train in a chassis to take to the event.

He has secretly hoped that he might have the fenders and maybe even the body attached.

By mid May he begins to question whether he will have a credible piece of hardware to take to the event.

During one restless nights sleep he seriously considers calling off his plan to take Bugsby to Hartford

and instead take a commercial air flight there and back.

At this point the engine has not been installed in the chassis and it is just

three weeks before he plans to hit the road for the drive to Hartford.

The bell housing, clutch, transmission, drive shaft, fuel tank, fuel lines, fuel pump,

generator, distributor, starter, carburetor, radiator, muffler and other

components have not yet gotten a proper cleaning and refinishing for installation.

Some of these items have unresolved issues likely requiring construction or repair.

Lynn's son Andrew says that it is "crunch time," referring to the final push to complete

a complex construction project before a hard deadline like often seen on reality TV shows like

"American

Chopper,"

"Junkyard Wars"

or "Monster

Garage."

If Lynn expects to have a running vehicle that is suitable for

close inspection by other Kissel owners in the next three weeks he will have to put out some serious effort

— and soon!

Lynn literally begins working around the clock to get Bugsby ready.

Working into the early hours of the morning, he often only gets about four hours sleep then goes to work.

After coming home from work he goes right to work in the garage, or if too tired, he takes

a short nap then goes to the garage.

For many days in a row Lynn doesn't get to bed before 1 am, and often works until 4 am or later.

Lynn's son Andrew devotes his weekends to helping Lynn with the work.

In the end, the extra pair of hands and muscles make the difference between success and failure.

The following is a brief pictorial review of the final push to get Bugsby ready for Hartford.

|

D-15:

Lynn completes the refinishing of the bell housing and assembles the clutch (left),

installing the engine in the chassis with the help of Andrew (center, right).

This single step has a huge visual impact as the chassis with the engine installed starts to look like

a car, again, encouraging Lynn to redouble his efforts.

|

|

D-15:

Lynn strips the old paint off the transmission (left) and refinishes it installing new fasteners

(center, right).

|

|

D-13:

Lynn is momentarily puzzled by a large fiber washer that he finds epoxied to the front face of the

transmission.

After some hours studying his

Dyke's Automobile Encyclopedia, Lynn

concludes that this is a home made clutch brake, a device that was not originally found on this year vehicle.

Apparently this has been added by an earlier restorer (probably Bill Trollope).

A clutch brake slows a fast spinning clutch while shifting.

An effective clutch brake would greatly help with smooth shifting so Lynn fabricates

a new brake out of cork and glues it to the face of the transmission.

Lynn will find later that this ad hoc modification is indeed very effective.

The clutch brake is so effective that Lynn can actually slow the car by pressing on the

clutch pedal after the clutch is has been disengaged.

|

|

D-13 (May 29, 2006):

Andrew connects the drive shaft to the differential after the transmission is installed (left).

Lynn installs a park bench as a temporary seat for the driver and a passenger (center).

Lynn is inspired by pictures he has seen of Kissel mechanics test driving chassis around Hartford

sitting on an orange crate tied to the frame with rope.

After the radiator is installed Andrew tries out the driving position (right).

|

On D-11 Lynn leaves on a two-day business trip to New Mexico. While sitting on the airplane

Lynn thinks through the steps he still needs to take before the car will be ready for Hartford.

He prepares an ordered list of 35 items that need to be completed over the next 7 days.

Yikes!

Lynn's wife Jeanne offers some words of encouragement — "That just five items per day."

Yes, but some of those are big items. Lynn tightens his belt, puts his head down and charges ahead.

|

D-7:

Over three days, Lynn makes good progress. He completely disassembles, cleans and

reassembles the mechanical brake linkage (left).

All of the brake pivot points and shafts were completely frozen from corrosion and it took considerable

effort to work everything free.

Lynn is really pleased with the result and thinks the brakes will be much more effective now that

the mechanical equalization between left and right sides is working.

Lynn orders all new clevis pins for the brake linkage.

The muffler is disassembled, painted and reassembled with new allthread rods and fasteners (center).

A refinished starter with new fasteners is installed (right).

|

|

D-7:

The generator and distributor are refinished and installed, new fabric covered spark plug wires

are installed, and the nickel plated spark plug loom is polished (left, left center).

Period correct two-piece Champion C-4 plugs are installed.

Lynn intends to finish all the chassis wiring ends using the period correct technique of whipping the ends

with cord and coating with clear dope, a touch that

Dave Arnold applied to

DeWayne Ashmead's car (right center, right).

|

|

D-7:

The fuel tank and new fuel line are installed (left).

Lynn installs a modern inline fuel filter (left center) that will be difficult to see once

the body is back on the frame. He installs valves to isolate the filter during replacement.

Although Dave Arnold has reconditioned Lynn's

Stewart vacuum fuel pump, Lynn is unsure that it will operate correctly.

Because of the limited remaining time, Lynn installs his old electric fuel pump thinking that

its operation is a sure bet (right center).

Remarkably the electric fuel pump causes nothing but trouble and fails to operate correctly.

After some frustrating hours trying to get the electric fuel pump to work, Lynn completely

removes it and the complicated network of fuel lines that he had created around it from the car.

Lynn installs the Stewart pump (right) that Dave rebuilt and crosses his fingers.

Praise be to Dave Arnold! The Stewart pump immediately worked and has worked flawlessly since.

|

|

D-6:

More hours lost!

The thin AREMCO Pyro-Putty™ 2400

coating that Lynn has applied to the exhaust manifold to fill orange-peel pitting is separating

from the manifold and peeling!

Lynn uses an angle grinder and wire brush to remove all the old coatings and applies a single layer of

AREMCO 1200°F Pyro-Paint™ (left).

Following what he saw on DeWayne Ashmead's 1925 Kissel Speedster, Lynn uses a rotary tool and wire

brush to polish the Stromberg OS-2 carburetor on Bugsby (center).

Lynn uses a musical instrument clear lacquer spray that he purchased from

Restoration Supply Company to coat the brass hoping to

retard future tarnishing of his beautifully polished carburetor.

Lynn constructs a simple instrument panel from 3/4" oak plywood

to hold the starter and ignition switches, and the ammeter and oil pressure gauges (right).

On a whim, Lynn mounts the car number plaque to the panel.

|

|

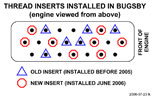

D-4:

Disaster strikes, will this sabotage Lynn's plans!?

Multiple head bolts won't torque to 65 ft-lbs — some won't even torque to 50 ft-lbs.

Off comes the head and the offending threads are drilled out and tapped to accept new thread inserts

(center, right).

Dan from D&M Machine Shop made Lynn a tool that is

a life saver. The block of soft machine steel has three holes — one (slotted) to secure the tool to

the block using a neighboring bolt hole; one (smooth) to guide the drill bit used to clean out the old threads;

one (threaded) to guide the tap used to cut the threads for the new thread insert.

Lynn uses this simple but very effective tool to replace the threads on five head bolt holes.

He uses the magnet at the end of an inspection mirror to draw the metal filings out of the block.

|

|

D-2:

Lynn adds coolant and water wetter to Bugsby's radiator (left).

What's that? The water pump leaks!

The bolts that hold the clam shell halves of the water pump together are open through to

the water chamber and the water is weeping past the threads.

With an increasing sense of dread, Lynn uses a plastic coffee canister and wire for a handle to fashion

a bucket to catch the coolant that's slowly dripping from the water pump.

Happily the car starts right up on the first try in the early morning hours of Friday, 7/9 — D-2.

There is no throttle, only an idle setting to control the engine speed, but the car runs!

Lynn trailers the car to California Reflections

to fulfill a promise he made to Kevin Schell a couple of weeks ago.

Beto and Kevin (center) are performing the work on Bugsby's body and they say that seeing the

chassis and running engine have inspired them.

Kevin poses with the body as it appears on this date (right).

|

|

|

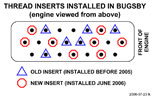

D-1:

When Lynn gets Bugsby home after the visit to the body shop, he re-torques the head bolts.

Will it never end? Three more bolts will not torque.

Next day, D-1 (June 10, 2006), on the day before he's to leave on the trip to Hartford, Lynn

has the head off Bugsby, again.

He drills, taps and installs three more thread inserts.

Lynn prepares a "map" of the head bolts on Bugsby, noting which holes have original threads, old inserts

and the new inserts that he's install during the last week.

Bugsby has 22 head bolts. Of these, only 8 holes have their original threads.

Lynn wonders if it would be a good idea to go ahead and install thread inserts in the remaining

8 holes.

|

|

D Day:

Bullet (2004 Pace American Shadow GT 20' car trailer) is connected to the Beast

(2003 Ford F-250 truck).

Bugsby and assorted tools and equipment are loaded and tied down inside, ready to depart for Hartford.

|

Lynn is exhausted, but he's managed (with support and understanding from Jeanne and

considerable help from Andrew) to get a running chassis that he can take to Hartford.

Lynn had intended to do more to get his trailer ready such as installing cabinets, mounting his

fire extinguisher and other items.

Looks like all that will have to wait for another time.

Lynn grabs an assortment of tools and equipment and stacks it on the floor of the trailer up

against the front wall.

At about noon on June 11, 2006, Lynn, Jeanne, Bugsby, Bullet and the Beast pull away from the

curb of their home in Livermore.

Andrew will be flying out later to join them in Hartford.

How will Lynn and his incomplete hunk of metal be received in Hartford?

Lynn is too tired to worry about that now.

Read about how the event unfolds in Lynn's description of the

100 year anniversary celebration

of the Kissel Motor Car Company.

Contact  with your comments or questions with your comments or questions

Copyright © 2018 Lynn Kissel

Last updated: May 24, 2009

|

with your comments or questions

with your comments or questions