The Serious Freshening

Go to <Last, Summary, Next>Engine—Gasket Set Templates

Lynn in Bugsby, September 5, 2005 |

Revised: 2006-09-30 — Started: 2006-07-28

VALVE-COVER GASKET: Print these PDF files to create a full-sized template of the gasket — part1, part2, part3. |

OIL-PAN GASKET: Print these PDF files to create a full-sized template of the gasket — part1, part2, part3, part4. |

EXHAUST-MANIFOLD GASKET: Print this PDF file to create a full-sized template of the gasket — part1. |

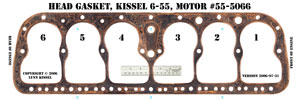

HEAD GASKET: Lynn finds "Victor 50-" and "McCord 5048" part numbers on some of the spare head gaskets that he received with the car. Print these PDF files to create a full-sized template of the gasket — part1, part2, part3, part4. |

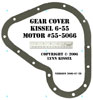

TIMING-GEAR-COVER GASKET: Print these PDF files to create a full-sized template of the gasket — part1, part2, part3, part4. |

COOLING-SYSTEM GASKETS: Print this PDF file to create a full-sized template of the gaskets — part1. |

OIL-BASIN REAR GASKET: Print this PDF file to create a full-sized template of the gasket — part1. |

Work Completed:

Lynn has created these templates for making additional gaskets for the engine of Bugsby.

It is likely that they may be useful to other model 6-55 owners.

Motors up to 55-4999 are first series Model 55 motors. Motors 55-5001 to 55-5999 are motors with full pressure oiling systems and gear drive. Motors 55-6001 and up are motors with full pressure oiling systems and chain drive. Bugsby's motor 55-5066 is one of the early issues of the full pressure oiling system motors.

The PDF templates noted in the captions are designed to be printed on 8.5"x11" paper to create a full-size template suitable for cutting new gaskets. Note that the default settings on some computers will automatically scale the printout to fit the page leaving a nominal margin. Check that the scale of your final output is correct by comparing the length of the ruler that is embedded in the templates. Lynn has successfully printed these templates on his personal computer once it was configured to print the files without scaling.

For the templates that require multiple sheets, small light-blue alignment marks are embedded in the template. It should be a relatively easy matter to trim the printouts and align them using the marks. Cellophane tape can be used to create the final full-size template.

While creating these templates, Lynn notices that the head gasket is not symmetric. The holes between cylinders 1-2 and 3-4 that connect the water jacket of the head to the water jacket in the block are larger than their counterparts between cylinders 4-5 and 5-6. Before this Lynn had thought that the gasket was symmetrical in spite of repeated inspections. These non-symmetric holes are likely used to balance water flow through the block and head, with the smaller holes in the back forcing more water flow to the front of the block. Lynn wonders how he's installed the gasket that's currently in Bugsby. There's a 50% chance that it's installed backwards.

WATER FLOW THROUGH KISSEL SIX: To implement this flow through the block and head, the large holes of the head gasket must be installed toward the front of the engine. |

(When initially creating this page, Lynn used the imprint left on the gasket from its earlier installation in the motor to determine the "correct" orientation of the gasket. He concluded incorrectly that the large holes are to be installed in the back based on this earlier installation. After looking through his materials from the Kissel archives that he collected in Hartfort on June 18, 2006, Lynn saw this information in an early 1920's sales brochure that distinctly shows that the large holes need to be in front. See Trawling the Kissel Archives.)

The oil-basin rear gasket seals a small sheet-metal plate that bolts to the rear of the oil pan. This plate is used to catch oil that flows past the rear main crankshaft bearing and route it back into the oil pan through some drain holes.

These gasket templates are free for use by individuals who do not offer them for sale.

Work Remaining:

None.

Contact

with your comments or questions

with your comments or questionsCopyright © 2018 Lynn Kissel

Last updated: May 24, 2009